Tower Tents, 2007-2011

also called: King Abdul Aziz Endowment / Abraj al Bait

Contractor: Rasch + Bradatsch (former Frei Otto)

Client: Kingdom of Saudi Arabia / Saudi Bin Ladin Group

Scope: Tops of five towers / lightweight structures design and planning

The second-highest building in the world (601m), with the largest floor area, is constructed as part of the King Abdul Aziz Edonwment.

It consists of a base with seven towers rising into the sky, and stands next to the central mosque in Mecca, the most prominent location in Saudi-Arabia.

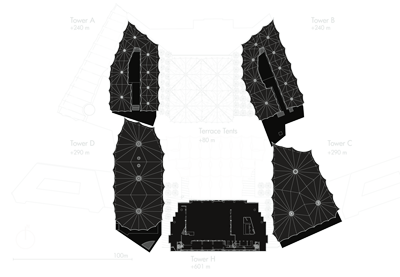

Our scope was the design and planning for the tops of five of the towers, desired to be as lightweight as possible.

Tower A and B got membrane structures resembling groups of beduin tents, and containing rooms for the royal family.

Tower C and D got membrane structures of a larger scale, containing a restaurant and a common lounge.

Tower H, got a steel structure with four huge clocks on the outside, with diverse usage inside.

The membranes are minimal surfaces, based on research and theories with soap films carried out by Frei Otto.

I was engaged in the planning and design of all towers, mainly membrane works.

Most significant: developing methods to generate and later produce ornamented membranes, and afterwards leading the teams responsible for the inner membranes of Tower B, C and D.

Gross floor area: ca. 12.000 m²

Towers A and B

The two frontal towers, A and B, have a height of approx. 240 m.

On the top they contain rooms meant for the royal family.

Part of it is private, part is prepared for representation purposes, royal functions etc.

They have different shapes, but the concept and the assembly are the same.

They are shaped as agglomerations of tents and, set to the scale of the building, resemle groups of beduin dwellings.

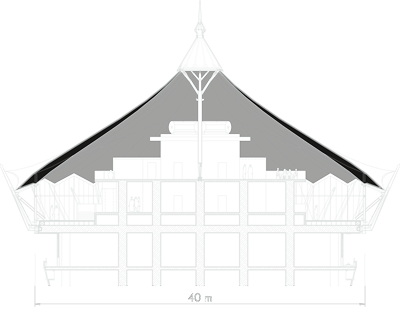

The shape is mostly defined through membranes, whose geometry is generated as minimal surfaces.

As the client desired to have no masts in the centers of the tents, as would usually be the most efficient way of construction,

a steel structure following the outer tents’ shape is built.

Additionally the interior design does not follow the outer shape.

To bridge the interior design and the shape, and to cover the steelwork, insulation etc., an independent inner membrane is constructed.

Ornamented to fit the local architecture and the needs of the client.

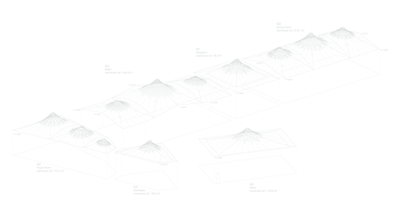

Towers C and D

- Under Construction -

Tower C and Tower D have a height of approx. 290 m.

On the top Tower C contains a restaurant and Tower D common lounges.

They have wide spanning spaces.

The shape is defined by three huge tent-shapes.

These are generated as minimal surface membranes.

This time the centers have masts, so no steelstructure is needed.

The inner membranes are still needed to cover the insulation and other installations,

and have a non-geometric ornamentation fitted to the leisure character of the usage.

For both towers the design, planning and production is finished.

The installation is as of now (Summer 2011) still in progress .

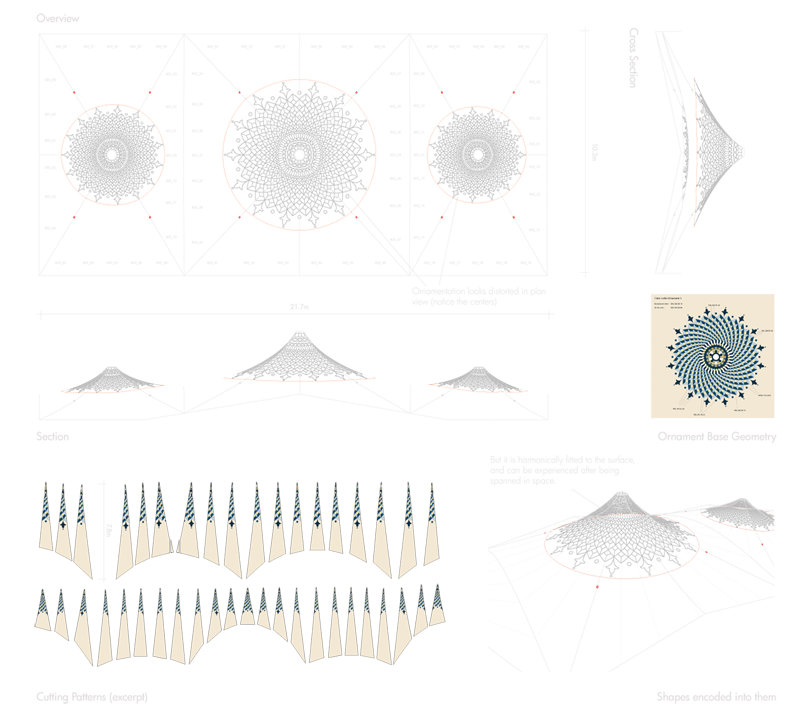

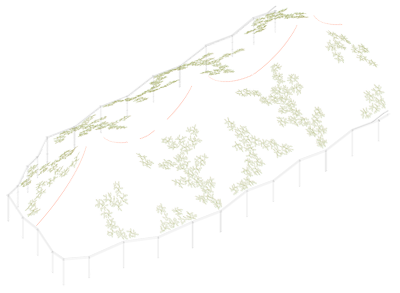

Inner Membranes Towers A to D

The membrane sturctures on top of the towers A to D have two membrane layers.

The outer membrane gives protection from natural elements, especially wind loads, and defines the outer shape.

The membrane and it’s details are mainly defined through forces and the need for stability, while they are always looked at from greater distances.

The inner membrane closes the contained spaces, hides the installations and is fitted to the interior design containing ornamentation as desired by the client.

Above all the ornamentation requests now that each point on a cutting pattern (and not only the edges) ends up exactly on the designed position in space.

It requires a much higher precision and new methods of generating and handling the membrane.

Here the membrane and the detailing is defined through the need for a perfectly smooth appearance,

especially because of the short viewing distance, while still being a mathematically sophisticated minimal surface.

I was responsible to deveop methods to generate ornamented membranes and afterwards high-precision cutting patterns for production.

This was accomplished accessing existing knowledge of the office, basing on research by Frei Otto.

The resulting tools are unique, and so the office is worldwide the only one capable producing ornamented membranes as minimal surfaces.

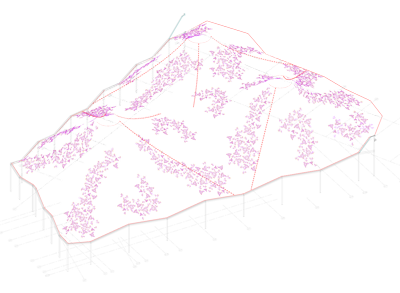

Tower B - Majlis (603) - Inner Membrane

Shown here is the ornamentation for one room, Majlis (603) on Tower B. A basic ornament pattern logic is generated onto a minimal surface. The goal is to have an ornament like naturally grown on it. Afterwards the geometry including ornamentation gets developed into 2D. Since it is a double-curved surface, distorsion occurs. For that purpose an algorithm considering material behaviour is used, making it possible to produce those shapes out of fabric. The contained ornament is continual, even the tangency of the elements is maintained.